Ceramics not only have excellent high temperature resistance, chemical corrosion resistance, corrosion resistance and good biocompatibility, but also have excellent and special electrical, optical, magnetic, piezoelectric and thermoelectric functional properties, which are widely used in mechanochemical, biomedical and other functional properties. , electronic appliances, new energy, nuclear power, aerospace, national defense and other fields. Today, let's take a look at one of its subcategories: ceramic bearing materials.

Ceramic bearings are a general term that can be subdivided into full ceramic bearings and hybrid ceramic bearings (semi-ceramic bearings). Common ceramic materials in bearings are: silicon nitride, alumina, zirconia and silicon carbide. 1. Hybrid bearings Hybrid ceramic bearings are generally assembled from bearing steel rings and bearing-grade silicon nitride rolling elements, which have electrical insulation properties. Advantages of hybrid bearings compared to bearings with steel rolling elements include:

(1) Prevent current corrosion When the motor is running, the potential difference between the two ends of the rotating shaft or between the shaft and the shaft is called the shaft voltage. If the two ends of the shaft form a loop through the motor frame, etc., the shaft current will be generated under the action of the shaft voltage. The shaft current is generated by the shaft voltage through the closed loop formed by the motor, bearing, stator frame or auxiliary device. Because the shaft voltage is low under normal circumstances, the lubricating oil film in the bearing can play an insulating role and restrain the shaft current from being generated; but when the shaft voltage is If it is higher, or when the oil film is not formed stably at the moment of motor starting, the shaft voltage will cause the discharge breakdown of the lubricating oil film to form a path to generate shaft current.

The high temperature generated by the partial discharge energy release of the shaft current can melt many tiny areas on the inner ring, outer ring or ball of the bearing, and form grooves, resulting in noise and vibration. great influence. The most significant feature of the electrical corrosion of the bearing by the high-frequency shaft current in the variable frequency speed control system is the "washboard"-type dense groove stripes on the inner and outer rings and balls of the motor bearing. What are the ways to fundamentally eliminate the shaft current of the motor? One is to increase the leakage device, that is, to install a bypass brush, so that the shaft current bypasses the bearing and drains; the other is to use an insulating bearing to block the path of the shaft current passing through the bearing. In order to block the shaft current path, at least one end of the motor must be Use electrically insulated bearings.

Axle currents often occur in wheelset bearings and traction motors (rail vehicles), DC and AC motors (power transmission systems), and generators (wind power). Shaft currents can cause damage to raceways and rolling elements and aging of lubricants, resulting in premature motor or generator failure, increased maintenance costs, and loss of production downtime.

The best solution to these problems is to use electrically insulated bearings. Bearings with ceramic coatings on both the inner and outer rings are called insulated bearings. The ceramic coating can prevent the passage of current and has the ability to insulate. The rolling elements of hybrid bearings are made of ceramics, which prevent the passage of electric current, so they also have insulating ability, and have a longer lasting insulating ability than ceramic coatings.

(2) Effectively increase the speed. The density of silicon nitride rolling elements is 60% lower than that of bearing steel rolling elements of the same size. Lighter weight and inertia result in higher speed performance, which makes the bearing exceptionally fast to start and stop. In addition, the ceramic ball has oil-free self-lubricating properties, and the friction coefficient of the ceramic ball is small, so the ceramic ball bearing has a high speed. According to statistics, the bearing using the ceramic ball is more than 1.5 times the speed of the general bearing. Hybrid ceramic bearings have been successfully used in the spindle of high-speed machine tools and have entered the practical stage, such as HPM ultra-precision lathes produced by Makino and other companies in Japan. In the high-speed machining center, the spindle speed has reached 42000r/min, and the cutting speed has been increased by 5~10 times. In addition, hybrid ceramic bearings are also used in high-speed equipment such as electric spindles and eddy current molecular pumps.

(3) Long service life The heat generated by friction in the hybrid ceramic bearing is low, especially at high speed, which helps to prolong the service life of the bearing and prolong the relubrication interval, which can greatly reduce the downtime loss and maintenance cost caused by bearing maintenance. Increase.

(4) High hardness and high toughness silicon nitride rolling elements have higher hardness and excellent toughness. The combination of these two characteristics can obtain better surface roughness, and can prevent the damage of external hard particles and impact , Strong wear resistance.

(5) The bearing stiffness is higher The stiffness of the bearing refers to the degree of elastic deformation of the bearing under load. Stiffness affects all aspects of bearing vibration, noise, life and rotation accuracy, and is an important performance parameter in bearing analysis. This deformation is generally small and negligible, but in some applications, such as bearings for machine tool spindles or pinion bearings, stiffness is very important. The hardness of silicon nitride ceramics is 1 times higher than that of bearing steel, and the elastic modulus is about 1/3 higher. Under the same load conditions, the elastic deformation of silicon nitride ceramics is small. Therefore, the machine tool spindle using ceramic ball hybrid bearings has good performance. running accuracy.

(6) Low sensitivity to temperature changes Silicon nitride rolling elements have a low thermal expansion coefficient, and a small thermal expansion coefficient helps to reduce the sensitivity to temperature changes, thereby preventing sticking. For hybrid roller bearings, the applicable operating speed range is wider. At present, ceramic hybrid bearings are widely used in electric motors, aerospace applications, high-performance racing cars, laboratory equipment, underwater applications, etc. The demands for higher speeds, lower friction and longer life are easily met with ceramic hybrid bearings.

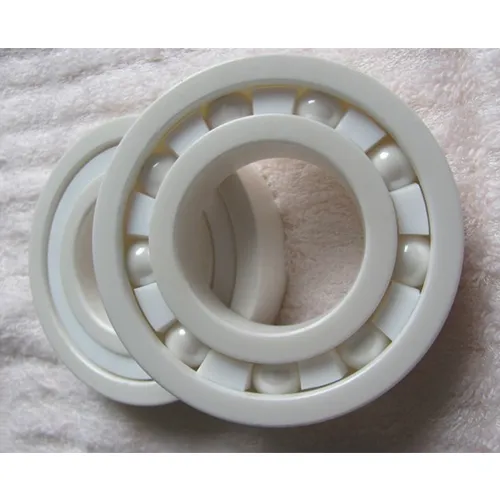

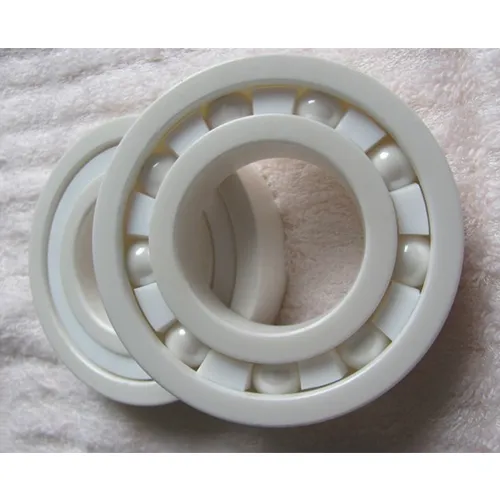

All-ceramic bearings The races and balls of all-ceramic bearings are made of ceramic materials. Compared with hybrid bearing materials, all-ceramic bearings are more difficult to process. Although hybrid bearings have performed well in many applications, there are a very limited number of them.

All-ceramic bearings are divided into those with retainers and those without retainers. All-ceramic bearings without retainers can continue to operate at extremely high temperatures. All-ceramic bearings have a high degree of corrosion resistance and can withstand most common Acids, they do not corrode when exposed to water or salt water.